Bicycle inner tubes are the most common type of puncture repair kits available. They are also just as varied and confusing as the number of different brands and types that are on offer. For tips about how to choose bicycle tubes, see this article.

1.Choose the big brands of bicycle inner tubes.

The inner tubes of big brands often mean better quality and stricter quality management in the production process. With advanced technology and production equipment, they can maximize the life of the products you use. Years of brand development mean higher quality assurance.

2. Choose the correct specification and model.

Before replacing a new bicycle inner tube, please determine what kind of inner tube you need. If you are not clear, please check the outer tire of your bicycle and usually mark the size on the side wall. For example, 26×1.95 or 700x35C and so on. When choosing a bicycle inner tube, you can choose the 26×1.75/2.125 inner tube because the inner tube expands when inflated, just like a balloon, so an inner tube labeled 26×1.75/2.125 can be used in 26×1.75 ,26×1.95 and 26×2.125 tires. Of course, the ideal match is to use the same size inner tube and outer tire.

3. Check the quality of the inner tube.

- After buying a new bicycle inner tube, check the packaging first to see if it is produced and sold by a good company.

- After opening the package, you can smell it first. if the smell is more pungent, it means that the inner tube contains more recycled butyl rubber, or low-end natural rubber (very pungent).

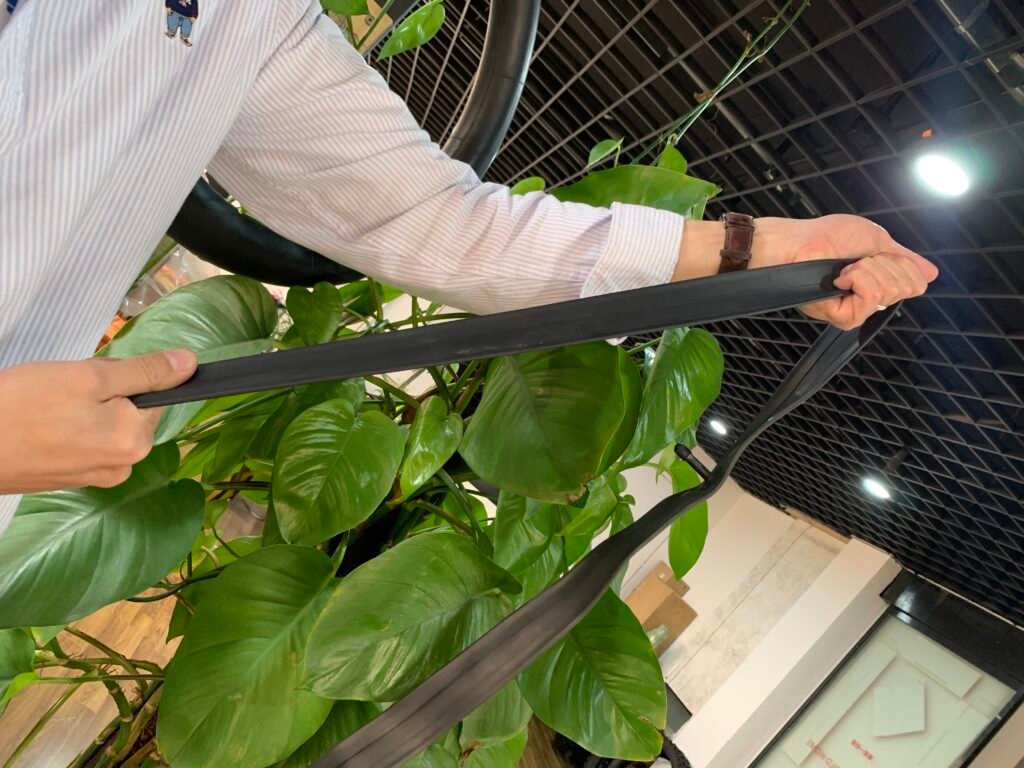

- Try to pull the inner tube to see if it has enough elasticity. If the elasticity is sufficient, it means very high-quality rubber raw materials, has better tensile strength and elongation, can be used more durable.

4. Observe the surface of the inner tube.

Take a close look at the whole inner tube to see if any small hole, defective rubber, or rough surfaces. A defective inner tube can cause air leakage due to pressure during cycling.

5. Check the valve.

Check the valve carefully to see if the rubber at the bottom is cracked. Cracking will lead to air leakage during use. In addition, check whether the parts on the valve are easy to disassemble, especially DUNLOP VALVE , because dunlop valve installed by the machine, when the torque is too large, it will difficult to remove the accessories . You will be pain in ass during the installation process.

IFAN produce the high quality inner tube with a very attractive price. If you are a local importer or distributor, please feel free to contact us. Check our website below:

2 Responses

Thanks for sharing this Article, Glad to see this such a wonderful blog.

Thanks for the comment, we would like to share more useful information in the future.